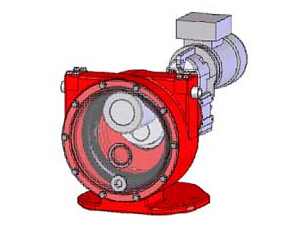

Metering & Dosing PumpsLarox Peristaltic PumpsThe innovative Larox Peristaltic Pumps for Dosing (LPP-D) and Metering (LPP-M) set a new industry standard for peristaltic pump technology. Designed and manufactured for the industrial marketplace, they are ideal for pumping diverse slurries and dosing a wide range of media. Peristaltic Pumps for Transfer are designed for heavy industrial duties. The LPP-T pumps are ideal for transferring abrasive, corrosive, viscous or crystallizing media.

One Compression is All You Need A single, bearing-mounted roller presses against the hose only once per the 360 degree operating cycle, producing the maximum flow per revolution and offering the longest lifetime possible. Unique Rolling Design Larox LPP-T pumps incorporate an advanced design, which eliminates friction, maximizes hose lifetime, and lowers energy consumption. The roller is mounted on a crankshaft creating eccentric rotation during the 360 degree operating cycle. Compared to conventional peristaltic pumps, the LPP-T pumps double the flow per hose compression. The Operating Principle of a Peristaltic Pump The operating principle of the LPP-T pump is based on the peristaltic effect. As the cylindrical rotor rotates along the hose, the process medium gets pushed forward through the hose. At the same time, the hose behind the compression point reverts to its original shape creating a suction effect at the pump inlet port. As a result the hose bore gets filled with the medium. No backward flow can occur as the hose is squeezed tight by the roller. Peristaltic Pump for Metering: Excellent Chemical Resistance Proven tube from thermoplastic materials designed for chemical industry gives secure operating conditions for both environment and operators. Durable pump head and rotor material selections with optimized number of parts are ideal for corrosive operation environments. Rigid one piece rotor assembly enables one minute maintenance and easy cleaning of the pump head.  Superior Accuracy for you Processes Accuracy of metering in any application is the most vital property of a metering pump. Flow rate of the LPP-M metering pump is not affected by variation or the discharge pressure condition. Positive displacement of the tube bore with zero slip provides same output volume on every cycle. The compression point of the tube acts as self-cleaning check valve without clogging risk providing clear flow path with no possibility for vapor lock. Operating PrincipleThe operating principle of the LPP-M pump is based on peristaltic properties. There are two types of rollers in the rotor: occluding rollers and guide rollers. The occluding rollers push medium forward through the tube and guide rollers center the tube for correct alignment. As the occluding roller rotates along the tube, the process medium gets pushed forward through the tube. At the same time, the tube behind the compression point reverts to its original circular shape creating a suction effect at the pump inlet port. As a result, the tube bore gets filled with the medium. No backward flow can occur as the tube is always occluded tight by the roller. To speak with an APEX Larox peristaltic pump specialist call 866.563.2739. Apex Pumping Equipment - "We Supply Solutions!" |

Print This Page

Print This Page